Products that work

Industrial epoxy

floor coatings

What are epoxy floor coatings?

Epoxy floor coatings are a type of coating that is applied to the surface of an existing concrete floor. The coatings layers are made up of mixtures of epoxy resins and hardeners, which when combined create a durable, hard surface that is resistant to chemicals, impact, and abrasion. Epoxy floors are typically applied in thin layers, and can be customised with colours and finishes to create a unique look or add functionality (like creating an anti-slip effect). They are a common choice for industrial settings such as manufacturing plants, warehouses, and garages.

Contents

Epoxy floor coatings

come in systems

When we speak loosely about industrial epoxy floor coatings we are usually referring to a so-called system that is made of various layers, depending on the demands of the industrial setting. Some floors need to be much more resistant than others. This is determined for example by the type of chemical and mechanical loads that the floors will be subject to. If a floor is going to be used by people only, it needs less thickness and structural hardness than a floor which is going to be driven on with industrial vehicles.

All you need for a heavy duty high quality industrial floor coating

As you will see on the schemes below an industrial floor system can be built with up to 3 or more layers which include, primers, scratch layers and top coats or cast floors. Mavro offers all of the products that form quality industrial system of floor coatings including the primers that ensure a good adhesion basis for the subsequent layers and products that enhance resistance or bring an additional feature to the coating.

Mavrox® EP Rollcoat 2c is one of these kinds of products; a two component floor finish which improves the chemical and mechanical resistance of the industrial floor.

Mavrox® PU Topcoat 1C is another such enhancing product. This very durable, solvent free, 1 component coating made on the basis of moisture-curing polyurethane has a double use. By mixing into it granules or powder it can be used as an anti-slip finish for epoxy floor coatings. Read about its other type of usage in the category about anti-graffiti coatings.

What is an industrial epoxy cast floor

An industrial epoxy cast floor is a type of flooring that is created by pouring an epoxy mixture onto a surface, such as a concrete slab (some basic layers are applied in advance, ofcourse). The mixture is then spread evenly and allowed to cure, creating a hard, durable surface that is resistant to chemicals, impact, and abrasion. Industrial epoxy cast floors are often used in settings such as mechanical workshops, plants, warehouses, because they are extremely resistant to all kinds of chemical and mechanical loads and are easy to clean.

Mavrox® Heavy duty industrial epoxy floor coatings for the most demanding needs

Mavro International’s professional line of building chemicals products features – amongst others – high performance epoxy flooring systems for industrial environments, that guarantee long lasting quality, and durability for even the most demanding circumstances.

There are various industrial flooring systems at disposal, depending on what the exigence of the space is. Our Research and development department can even create a custom system for your specific needs.

To keep things accessible for you as a customer, the MAVROX™ floor coatings are divided into a number of standard systems. A floor system is a combination of 2 or more coating layers which provide optimal properties. Based on the schematic drawings you can easily see what properties the floor system has, how the layer build-up is and how much product you need.

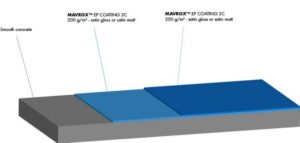

2 layers MAVROX™ EP COATING 2C (satin / satin matt)

Consumption approx. 200 grams per m2 per layer

- Light walking and driving load

- Most economical choice

- Improve chemical resistance

- Warehouses, garages, workshops, hardware stores, shops

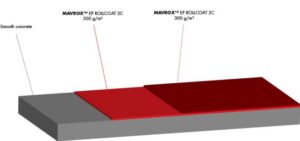

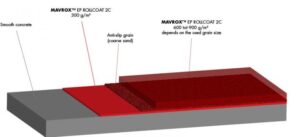

2 layers MAVROX™ EP ROLLCOAT 2C

Consumption first layer approx. 300 gram per m2

Consumption second layer depends on the desired layer thickness, 300-1000 grams per m2

- Intensive walking and driving load

- Higher chemical load

- Parking garages, warehouses, workshops

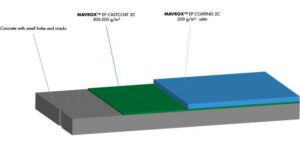

1 layer MAVROX™ EP CASTCOAT 2C (scratch coat)

Consumption depends on the flatness of the substrate 300-500 grams per m2

1 layer MAVROX™ EP COATING 2C (satin)

Consumption approx. 200 gram per m2

- Intensive walking and driving load

- Smooth and sleek finish by applying the scratch coat

- Higher chemical load

- Parking garages, warehouses, workshops

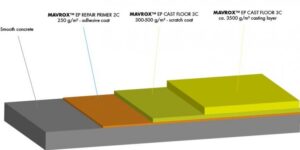

1 layer MAVROX™ EP REPAIR PRIMER 2C (adhesive coat)

Consumption approx. 250 gram per m2

1 layer MAVROX™ EP CAST FLOOR 3C (scratch coat)

Consumption depends on the flatness of the substrate 300-500 grams per m2

1 layer MAVROX™ EP CAST FLOOR 3C (casting layer)

Consumption approx. 3500 gram per m2

- Highly resistant both mechanically and chemically

- Seamless, hygienic & very durable

- Laboratories, Production areas, Cleanrooms

It is also possible to sprinkle the MAVROX™ floor with a grain to make the floor anti-slip. Depending on the grain size used, the floor gets a certain slip resistance. The slip resistance is expressed with an R-value where a high R-value is a stronger anti-slip effect.

1 layer MAVROX™ EP ROLLCOAT 2C

Consumption first layer approx. 300 gram per m2

Immediately after applying the first layer, sprinkle with quartz in the desired grain size:

0,1 – 0,5 mm (R12)

0,3 – 0,8 mm (R13)

0,6 – 1,2 mm (R13)

1 layer MAVROX™ EP ROLLCOAT 2C

Consumption depends on the used grain size:

0,1 – 0,5 mm: consumption approx. 600 gram per m2

0,3 – 0,8 mm: consumption approx. 750 gram per m2

0,6 – 1,2 mm: consumption approx. 900 gram per m2

- Intensive walking and driving load

- Higher chemical load

- Strong anti-slip, even in damp / wet conditions

- Parking garages, warehouses, workshops

How do you apply a floor system?

Installing a floor system (floor coating or cast floor) is not difficult and as long as the correct preparations are made, anyone can do it. This page describes which steps must be followed before you get started with the application of the floor coating or cast floor.

Before you start with the pre-treatment, it is important to know what type of floor you are dealing with. Concrete floors are common, but especially in new construction you will also encounter softer floor types such as cement screeds and anhydrite. It is important that concrete floors are at least 28 days old before they are treated.

Does the floor have an existing coat of paint? Then inspect it thoroughly: is the paint layer still completely intact or is it damaged? In most cases it is best to completely remove old paint layers. Read more about how to deal with existing paint layers here.

It is also possible to apply a floor coating over tile floors, follow the step-by-step plan for coating tile floors.

The inspection also includes determining the surface area in m2. You can calculate how much of each product you need based on the surface. The consumption of each product is different and can be found in the Technical data sheet (TDS). Always have enough material to avoid running out of material halfway through the project.

It is very important that the floor is thoroughly cleaned and degreased. Pay extra attention to stubborn oil or grease stains and then clean the entire floor again. Cleaning is done with a powerful alkaline cleaner such as Uniclean Low Foaming. After cleaning, the floor must be rinsed with water and it is best to remove the excess water with a wet vacuum cleaner.

To get a smooth and durable result, it is important that holes and cracks are repaired. You should preferably do this before sanding because it makes the repair less visible in the end result.

You can repair holes and cracks in the floor with Mavrox® EP Repair Mortar 2C. Are the damages very big? First apply Mavrox® EP Repair Primer 2C using a brush in the crack or hole. You can apply the repair mortar directly into the wet primer layer. This ensures that the filler adheres well.

Thoroughly roughening the floor is important to get good adhesion. Sanding a real concrete floor must be done with a diamond sander. Softer floor types can be sanded with grain 80 or 100 and should not be done using a diamond sander. You can rent a (diamond) sander from most tool rental companies.

If the floor is heavily soiled, you can also use sand-blasting techniques. Blasting removes the first few millimeters of the top layer, making the concrete floor look like new again. Blasting is also a good alternative to diamond sanding for very large surfaces. Blasting is generally performed by a professional.

After sanding or blasting, the floor must be completely dust-free. After all, you want the coating to adhere to the substrate and not to the dust. You can easily remove dust by vacuuming.

Before applying a floor coating or cast floor it is important to collect the right tools and materials. Depending on the floor system that is being applied, you will need the following materials:

- Spike shoes (to walk on the still wet epoxy floor)

- Electric drill with paint mixer attachment

- Telescopic handle

- Short-haired, lint-free rollers (for applying floor coatings) Use 18 or 25 cm rollers to apply the coating and use a 70 cm roller for re-rolling the coating to avoid roller tracks.

- Floor trowel or squeegee (for applying self-leveling floors and scraping layers)

- Prick roller / de-aeration roller (for re-rolling resin floors)

- Flat trowel (for applying scraping layers)

- Disposable brushes for corners and edge

- Masking tape

- Square bucket

- (optional) anti-slip grain for spreading the coating

Good rollers have a great effect on the appearance of the coating. Use a new roller for each layer, rinsing them out is not possible with 2-component coatings and is bad for the environment.

Safety obviously applies when applying floor coatings. MAVROX™ floor coating and cast floors are all water-based or solvent-free. However, careless use of the products can cause skin and eye irritation. With 2- or 3-component products, it is often the hardener that provides the odour, vapor and any irritations. Always work carefully and prevent your skin and eyes from coming into contact with the products. Always wear work clothes, nitrile gloves and safety glasses. In addition, ensure adequate ventilation, which is not only safe for the user, but also ensures that the floor coating dries faster.

It is important that paint residues do not end up in the environment. Do not rinse rollers and tools in the sink. Paint waste must be disposed of as small chemical waste, even if it has dried.

When in doubt, always consult the safety data sheet (SDS) or our R&D department.

When all preparations have been made, you can start application of the floor system. Follow the procedure described in the technical data sheet (TDS) to apply the MAVROX™ products. In the TDS you will find all important data about each product such as consumption, drying time and application conditions.

Below are shortcuts to each product information sheet:

MAVROX™ EP COATING 2C

MAVROX™ EP TOPCOAT

MAVROX™ CONCRETE PRIMER

MAVROX™ PU TOPCOAT 1C

MAVROX™ EP TILEPRIMER 2C

MAVROX™ EP ROLLCOAT 2C

MAVROX™ EP CASTCOAT 2C

MAVROX™ EP CAST FLOOR 3C

MAVROX™ EP SCRATCH COAT 2C

MAVROX™ EP GROUT 2C

MAVROX™ EP REPAIR PRIMER 2C

MAVROX™ EP REPAIR MORTAR 2C

Sed ut perspiciatis

Sed ut perspiciatis unde omnis

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo. Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt. Neque porro quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur, adipisci velit, sed quia non numquam eius modi tempora incidunt ut labore et dolore magnam aliquam quaerat voluptatem. Ut enim.

Present us with your challenge

We will figure it out for you!

What is your challenge? Chances are we have the solution. Need something that is not in our range? No problem. We will develop a tailor-made solution in our lab. Because we like to go the extra mile for you.

handig om te weten

laatste wet en regelgeving

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo. Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt. Neque porro quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur, adipisci velit, sed quia non numquam eius modi tempora incidunt ut labore et dolore magnam aliquam quaerat voluptatem. Ut enim ad minima veniam, quis nostrum exercitationem ullam corporis suscipit laboriosam, nisi ut aliquid ex ea commodi consequatur? Quis autem vel eum iure reprehenderit qui in ea voluptate velit esse quam nihil molestiae consequatur, vel illum qui dolorem eum fugiat quo voluptas nulla pariatur? At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas.

COFFEE IS READY

SIT WITH US,

LET’S CHAT

We would love to hear what is the surface cleaning or protection challenge that you face. It is quite probable that there is a product in our range of professional products that would solve your problem perfectly, and if there isn’t one, we might be able to create it. Let us know, use the button below.